3D Printing

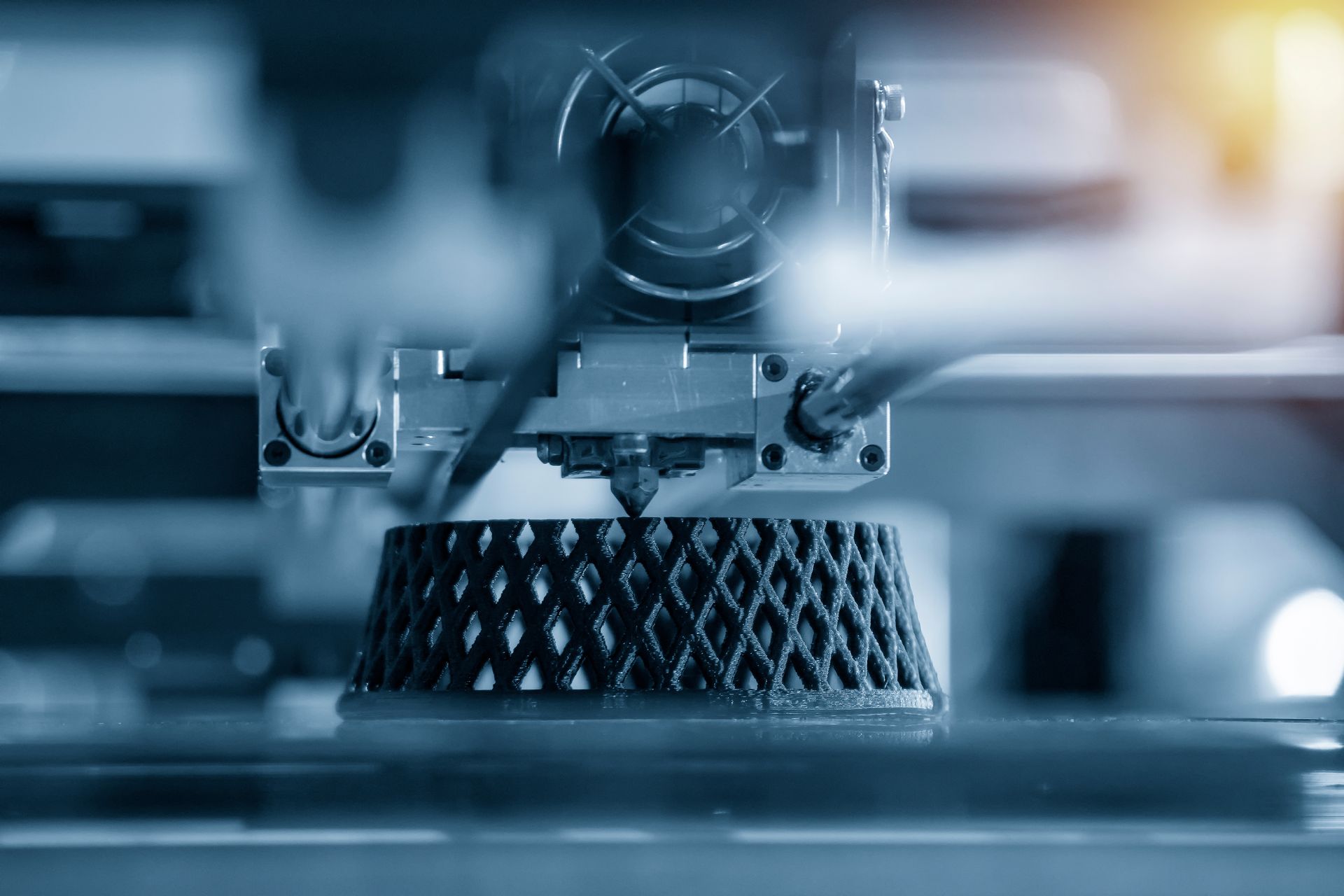

Fused Deposition Method (FDM)

FDM is a cost-effective, durable with large build volumes, versatile material options, and applications in prototyping, end-use parts, and custom tools.

Max Build Area: 1000 * 1000 * 1000mm

Application: Functional prototypes, low-volume end-use parts, custom jigs and fixtures, and educational models across industries like automotive, aerospace, and consumer products.

Material | PLA | ABS | PETG | TPU |

Tensile strength (MPa) | 63 | 43 | 52.2 | 35 |

Flexural strength (MPa) | 74 | 66 | 58.1 | NA |

Heat Distortion (°C) | 53 | 78 | 64 | NA |

IZOD Impact Strength (J/m) | 9 | 29 | 4.7 | NA |

Elongation at Break (%) | 20 | 22 | 83 | >=800% |

Flexural Modulus (MPa) | 1973 | 1177 | 1073 | NA |

Material | Carbon | Kevlar | Fiber Glass | Onyx | Onyx FR | Nylon | Onyx ESD |

Tensile Strength (MPa) | 800 | 610 | 590 | 40 | 41 | 51 | 52 |

Heat Distortion (°C) | 105 | 105 | 105 | 145 | 145 | 138 | 120 |

IZOD Impact Strength (J/m) | 960 | 2000 | 2600 | 330 | NA | 44 | 111 |

Elongation at Break (%) | 1.5 | 2.7 | 3.8 | NA | NA | NA | NA |

Flexural Modulus (MPa) | 51000 | 26000 | 22000 | 3000 | 3600 | 1400 | 3700 |

Continuous Fiber Reinforcement (CFR)

Industrial-grade manufacturing jigs, jaws, tools, fixtures, and end-use parts. Survive the production floor environment and printing parts stronger than machined aluminum for a fraction of the cost.

Max Build Area: 330 * 270 * 200mm

Application: Functional prototypes, custom jigs and fixtures, across industries like automotive, aerospace, and consumer products.

Stereolithography (SLA)

SLA offers high-resolution prints, smooth surface finishes, and is ideal for detailed prototypes, dental models, jewelry, and complex engineering parts.

Max Build Area: 800 * 800 * 800mm

Application: Detailed prototypes, dental models, jewelry patterns, and complex engineering components that require precision and fine surface finishes.

Material | Standard | ABS Resin | Flexible | Clear | Bio Medical | High Temp |

Tensile strength (MPa) | 65 | 34 | 7.7 - 8.5 | 36 | 52 | 43 |

Heat Distortion (°C) | 58.4 | 50 | NA | 55 | 67 | 130 |

IZOD Impact Strength (J/m) | 25 | 60 | NA | 30 | 35 | 48 |

Elongation at Break (%) | 6 | 20 | 75-85 | 10 | 12 | 8 |

Flexural Modulus (MPa) | 2200 | 1070 | NA | 1430 | 2300 | 2057 |

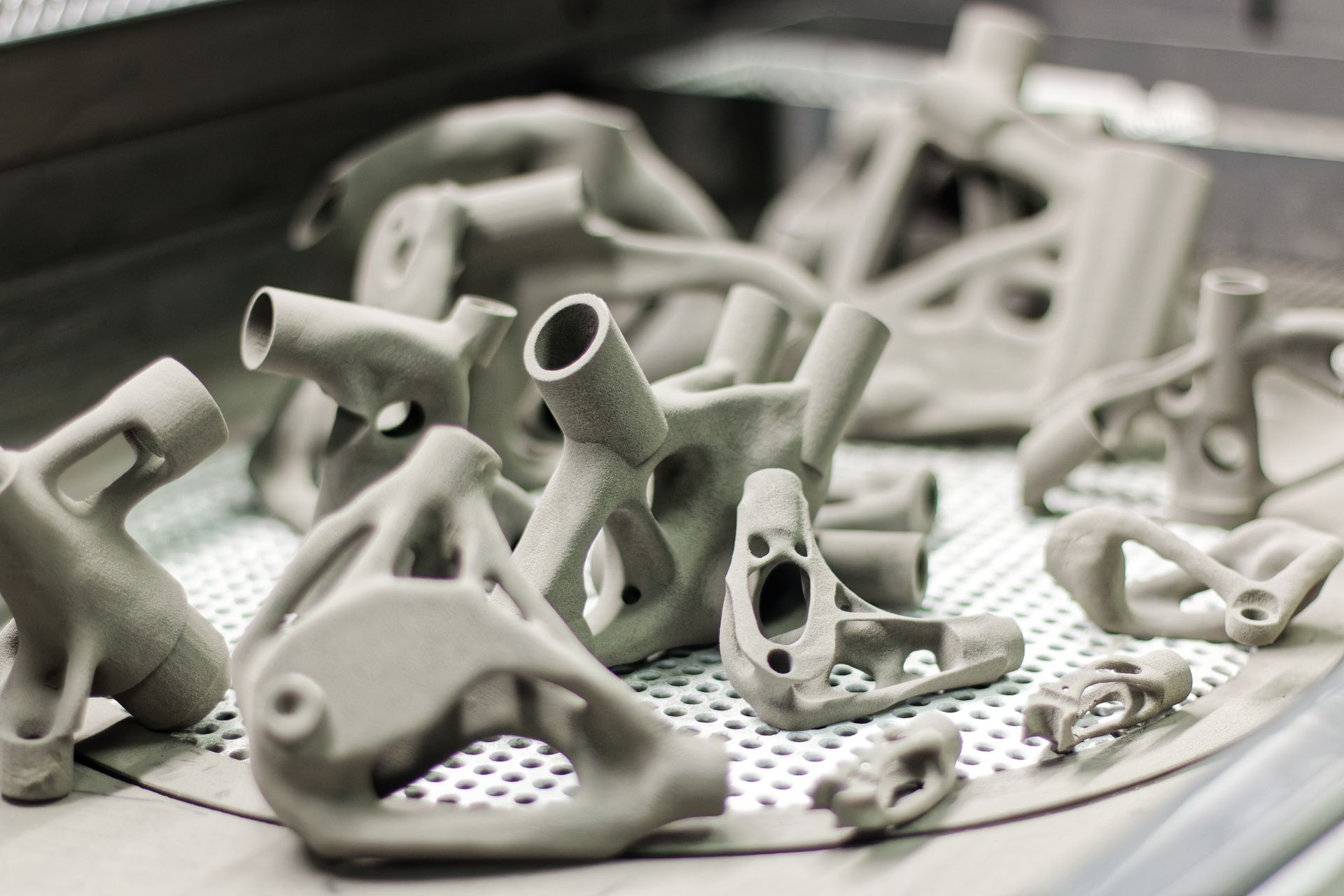

Multi Jet Fusion (MJF) & Selective Laser Sintering (SLS)

SLS and MJF both produce strong, durable parts with complex geometries; It delivers high-strength, detailed parts with smooth finishes and fast print speeds, ideal for functional prototypes and production runs.

Max Build Area: 380 * 284 * 380mm

Application: Functional prototypes, end-use components, and intricate designs in industries like aerospace, automotive, healthcare, and consumer electronics.

Material | SLS Nylon 12 | HP PA11 | HP PA12 |

Tensile strength (MPa) | 48 | 54 | 50 |

Flexural Strength (MPa) | 41 | NA | 70 |

Heat Distortion (°C) | 86 | 181 | 175 |

IZOD Impact Strength (J/m) | 4.4 | 7 | 3.6 |

Elongation at Break (%) | 20 | 40 | 20 |

Material | 316L Stainless Steel | Titanium (Ti₆Al₄V) | Inconel (IN718) | Aluminum (AlSi₁₀Mg) |

Tensile strength (MPa) | 600 | 900 | 940 | 250 |

Yield Strength (MPa) | 400 | 830 | 750 | 180 |

Elastic Modulus (GPa) | 180 | 110 | 200 | 70 |

Hardness after heat treatment (HV) | 271 | 310 | 300 | 80 |

Elongation at Break (%) | 30 | 10 | 8 | 1 |

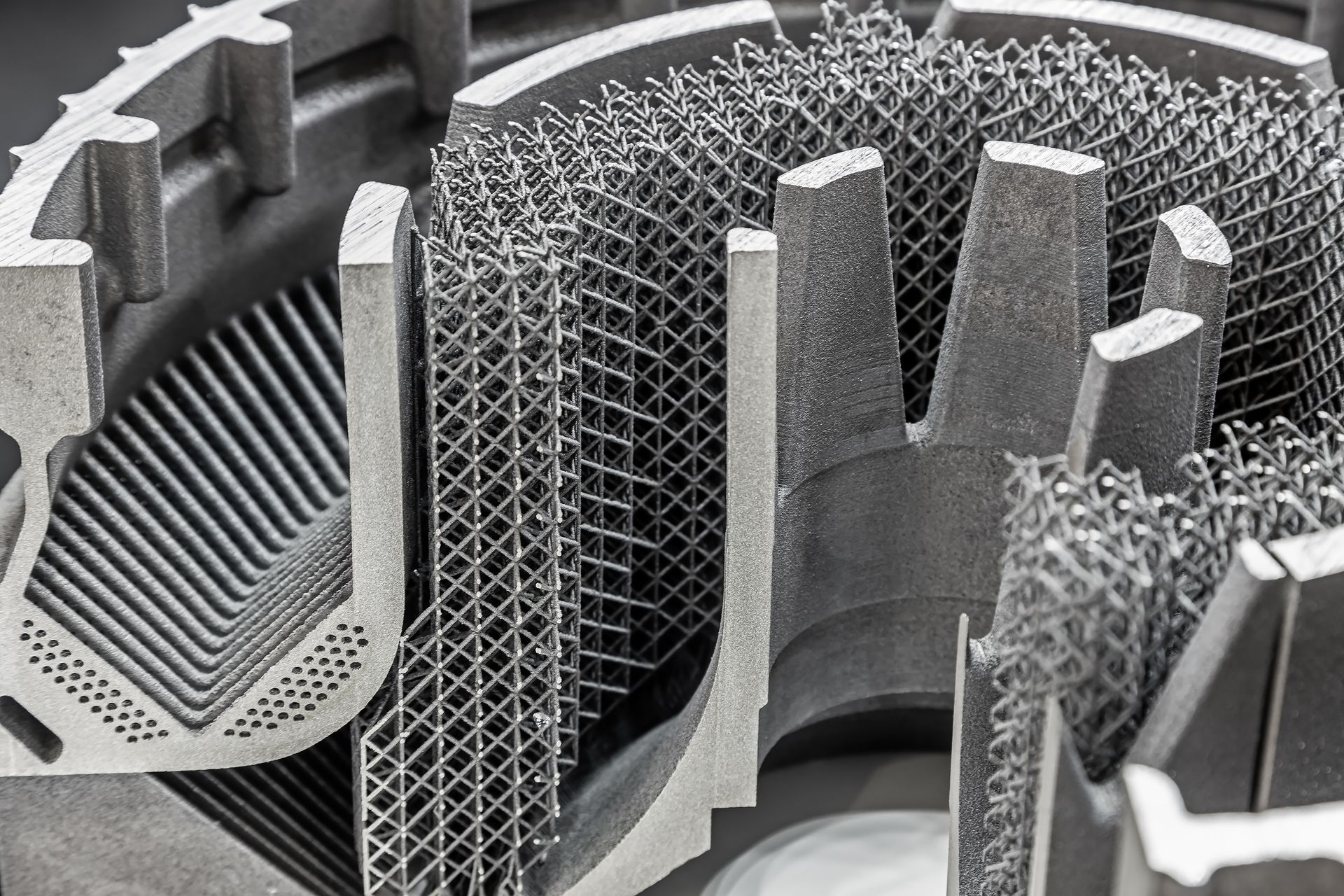

Metal Additive Manufacturing

Metal 3D printing offers high-strength, durable parts with complex geometries, precise details, and material efficiency, making it ideal for aerospace, medical implants, and custom tooling applications.

Max Build Area: 280 * 280 * 365mm

Application: Metal 3D printing is used for high-performance aerospace parts, custom medical implants, complex tooling and molds, durable automotive components, and precision-engineered industrial parts.